For collectors and practical users of vintage Singer sewing machines, key models differ in construction, features, and intended use. Focus on these historically significant options:

Core Vintage Models Compared

- Singer 15 (1879 onwards): The benchmark. Rotary hook mechanism (foundation for modern machines), uses common 15x1 needles still available today. Reliable, repairable, and abundant. Later versions (post-1920s) may have more pot metal components. Ideal for foundational vintage use.

- Singer 127/128 (Early 20th C - Oscillating Shuttle): Predecessor to the 15. Robust "vibrating shuttle" mechanism. Highly durable cast iron construction. Known for a distinctive, slightly different stitch quality than rotary hook models. Excellent for heavy fabrics.

- Singer 201 (1935 onwards): Pinnacle of Singer engineering. Gear-driven, exceptionally smooth, near-silent straight stitch. All-metal internal mechanisms. More complex, highly valued by enthusiasts for superior stitch quality.

- Singer 66 (1900s onwards): Workhorse model preceding the 15. Three-quarters size machine head, often with iconic decals ("Red Eye", "Sphinx"). Oscillating shuttle mechanism. Very robust, common in treadle bases.

- Singer 99 (1920s onwards): Compact version of the 66 (same mechanism). Portable/trunk models common. Excellent option for portability or smaller workspaces.

Critical Considerations

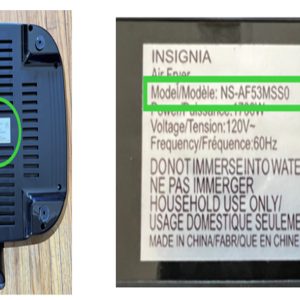

- Internal Construction: Prioritize all-metal internal gears. Machines pre-~1960 are generally superior. Later models incorporated pot metal that degrades or breaks. Check under the baseplate.

- Functionality Check: Verify essential functions: smooth handwheel rotation, free needle movement up/down, functional stitch length lever, feed dogs moving, hook race rotation (if 15/201). Ensure no internal grinding noises.

- Drive System: Identify treadle, hand-crank, or electric motor (often conversions). Treadle/Hand-crank ensures purity; original motors need rewiring/replacement for safety. Verify belt condition.

- Bobbin System: Oscillating (127/66/99) vs. Rotary (15/201). Parts availability slightly favors Rotary 15 type. Understand the loading method (vertical/drop-in vs. horizontal/front-loading).

- Condition & Maintenance: Thorough cleaning and lubrication are mandatory. Inspect for rust (especially bedplate), gear tooth wear, broken parts, bent shafts. Factor restoration costs/time if needed.

Modern "Heavy Duty" vs. True Vintage

Models like Singer 4423/4432 (Modern Heavy Duty Series) offer high speed and motor power for thick fabrics but lack the longevity, repairability, and stitch quality of pre-1960s all-metal vintage Singers. These modern machines serve different needs than collectors' or vintage purists' requirements.

Choose based on priorities:

- Simplicity & Repairability (Most Users): Singer 15 or 127/128.

- Ultimate Stitch Quality & Smoothness: Singer 201.

- Robust Basic Stitching & Portability: Singer 99 or 66.