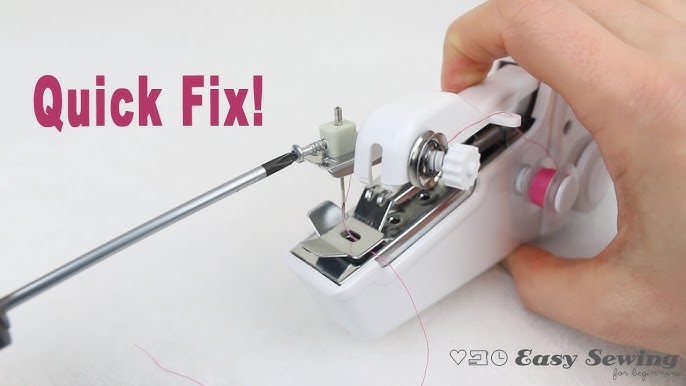

Miniature Singer sewing machines often experience basic stitch problems such as skipped stitches, uneven tension, or thread breakage. Address these issues swiftly to resume smooth operation.

Common Stitch Problems

Identify frequent issues for targeted fixes:

- Skipped stitches: Needle failing to catch thread.

- Uneven tension: Looping thread on fabric surface.

- Thread breakage: Frequent snapping during stitching.

Quick Troubleshooting Steps

Follow these sequential actions to resolve most basic stitch faults in minutes:

- Check needle condition: Replace bent or dull needles. Use new, quality needles compatible with fabric type.

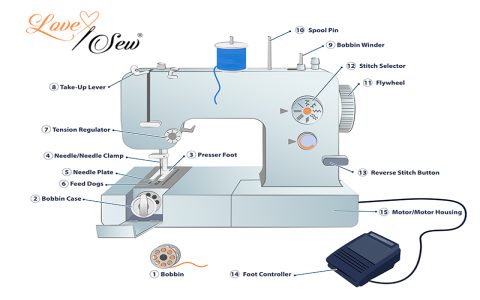

- Verify thread path: Re-thread the machine. Ensure thread travels correctly through all guides and tension disks without tangles.

- Adjust tension settings: Set upper tension dial to mid-range. Test on scrap fabric; fine-tune for balanced stitches (no puckering or loops).

- Clean lint buildup: Power off and remove the needle plate. Use a brush to clear dust and lint from feed dogs, bobbin area, and shuttle hook.

Perform these steps before re-testing stitches; avoid force on mechanisms to prevent damage.

Preventive Maintenance

Sustain optimal performance with simple habits:

- Regular cleaning: Brush lint after every project to avoid jams.

- Proper threading: Always thread with presser foot raised.

- Use correct supplies: Match needles and thread weight to fabric.

Quick fixes ensure reliable stitches, minimizing downtime.